In the ever-evolving world of industrial machinery, the right equipment is essential for ensuring efficient operations and maintaining safety standards. Various types of equipment play crucial roles in enhancing productivity, minimizing downtime, and ensuring the longevity of machinery. This article highlights some key pieces of equipment vital for industrial applications, including thermal imaging equipment and solenoid coils.

Thermal Imaging Equipment: Ensuring Optimal Performance

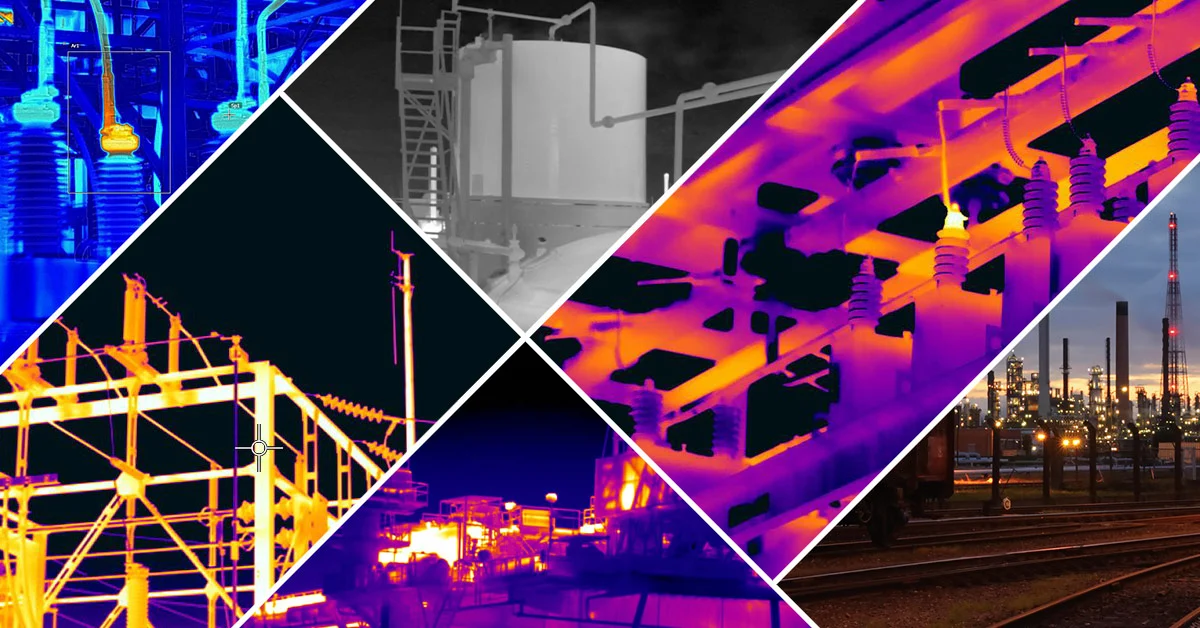

Thermal imaging equipment has become a game-changer in the realm of industrial thermal imaging. This technology allows operators to visualize and measure the thermal energy emitted by machinery and equipment, providing invaluable insights into their operational status. By detecting hot spots, thermal imaging can identify potential failures, overheating components, or insulation deficiencies before they lead to significant breakdowns or safety hazards.

In many industrial settings, thermal imaging is employed as a preventive maintenance tool, helping to ensure that machinery operates within safe temperature ranges. Regular thermal inspections can prolong the lifespan of equipment, reduce the risk of unplanned downtime, and enhance overall safety for personnel. As a result, investing in high-quality thermal imaging equipment is crucial for any industrial facility aiming to maintain optimal performance and efficiency.

Solenoid Coils: Custom-Made Solutions for Diverse Applications

Solenoid coils are another vital component in industrial machinery, acting as electromechanical devices that convert electrical energy into linear motion. These coils play an essential role in various applications, including valves, actuators, and switches. For many industries, Custom-Made Solenoid Coils offer tailored solutions that meet specific operational requirements and enhance overall performance.

Custom solenoid coils can be designed to fit unique specifications, allowing for adjustments in voltage, current, and force output. This customization is critical for industries where standard solenoid coils may not adequately perform or fit the machinery in use. By working with manufacturers who specialize in custom solenoid coil production, businesses can ensure that their machinery operates smoothly and efficiently, minimizing the risk of operational failures and downtime.

Vibration Analysis Equipment: Monitoring Machinery Health

Vibration analysis equipment is essential for monitoring the health of industrial machinery. By analyzing the vibrations emitted by machinery during operation, technicians can identify irregularities that may indicate potential issues, such as misalignment, imbalance, or bearing failures. Regular vibration analysis helps maintain optimal machinery performance and extends equipment lifespan.

Utilizing vibration analysis can also contribute to predictive maintenance strategies. By understanding vibration patterns and establishing baseline data, maintenance teams can pinpoint when machinery may need attention, reducing unexpected breakdowns. This proactive approach leads to significant cost savings and improves overall operational efficiency.

Lubrication Systems: Ensuring Smooth Operations

Proper lubrication is crucial for the seamless operation of industrial machinery. Lubrication systems ensure that machinery components receive adequate lubrication to minimize friction and wear. Automatic lubrication systems are especially beneficial, as they can deliver precise amounts of lubricant at scheduled intervals, reducing the need for manual intervention and ensuring consistent performance.

Investing in quality lubrication systems can prevent premature equipment failure, extend machinery life, and enhance overall efficiency. With the right lubrication in place, businesses can ensure that their machinery operates smoothly and reliably, resulting in increased productivity and reduced maintenance costs.

Safety Equipment: Protecting Personnel and Machinery

Safety equipment is an integral part of any industrial environment. Ensuring that workers are protected from potential hazards is essential for maintaining a safe workplace. Equipment such as safety guards, emergency stop buttons, and personal protective equipment (PPE) must be in place to prevent accidents and injuries.

Moreover, investing in advanced safety technologies, such as machine guards equipped with safety interlocks, can prevent unauthorized access to machinery while it is in operation. Ensuring that safety protocols are followed and that the necessary safety equipment is installed and maintained is crucial for protecting both personnel and machinery in any industrial setting.

Electrical Testing Equipment: Ensuring Reliable Power Supply

Electrical testing equipment is vital for ensuring that machinery operates safely and reliably. Equipment such as multimeters, insulation testers, and circuit analyzers help technicians diagnose electrical issues, monitor power quality, and ensure that electrical systems are functioning correctly. Regular testing of electrical systems can prevent unexpected failures and enhance overall operational efficiency.

By investing in high-quality electrical testing equipment, businesses can ensure that their machinery operates smoothly and that any potential electrical issues are addressed promptly. This proactive approach contributes to maintaining a safe and efficient industrial environment.

Conclusion

The efficiency and safety of industrial machinery depend heavily on the right equipment. From thermal imaging equipment and custom-made solenoid coils to vibration analysis and lubrication systems, each component plays a significant role in enhancing performance and ensuring operational reliability. By investing in the essential equipment outlined in this article, businesses can optimize their industrial processes, minimize downtime, and ultimately boost productivity. Prioritizing these critical components will lead to a more efficient and sustainable industrial operation.