In today’s fast-moving world, factories and industries are always trying to work faster, safer, and smarter. That’s where industrial automation comes in. It uses machines, control systems, and smart software to help businesses run more smoothly. But handling automation on your own can be tough.

That’s why many companies choose to work with an industrial automation control systems provider. These experts help design, install, and take care of the systems that keep factories running efficiently. Let’s look at five important reasons why working with one of these providers is a smart move.

1. Expert Knowledge and Experience

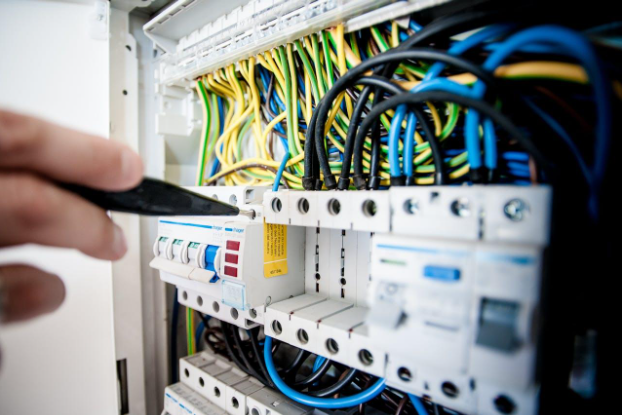

Industrial automation is not something you can figure out overnight. It involves many complex parts like sensors, controllers, and software. An Industrial Automation Control Systems Provider has trained professionals who understand all of these things.

They’ve worked on many projects before and know what works best in different industries. Their experience helps prevent costly mistakes and ensures that the system runs safely and correctly. With their guidance, you can feel confident that your factory or plant is in good hands.

2. Customized Solutions for Your Business

Every business is different. A food processing company doesn’t need the same system as a car manufacturer. A good automation provider will study how your business works and offer a solution that fits your specific needs.

They don’t just sell you machines—they create a system that improves how your whole operation runs. Whether you want to save energy, speed up production, or reduce waste, they can build a system that meets your goals.

3. Better Productivity and Efficiency

One of the main reasons companies turn to automation is to get more done in less time. Machines don’t get tired or take breaks, and they can do the same task over and over without mistakes. When an automation system is designed and installed correctly, it can help increase your production speed and reduce errors.

This means you can make more products, faster, and with fewer problems. That’s good for your customers and your bottom line.

4. Ongoing Support and Maintenance

Even the best machines need care to keep working well. A trusted automation provider offers support even after the system is installed. If something breaks down or needs an update, they’re just a phone call away.

This kind of support helps avoid long downtime and keeps your business running smoothly. They can also train your staff, update software, and check the system regularly to make sure everything is working as it should.

5. Staying Up to Date with Technology

Technology is always changing, especially in automation. New tools and software are coming out all the time to make factories even smarter. When you work with a provider, they help you keep up with these changes.

They’ll let you know when it’s time to upgrade or try something new. This way, your business stays modern and competitive, instead of falling behind.

Conclusion

Working with an industrial automation control systems provider is a smart choice for any business that wants to grow, save time, and improve quality. These experts bring valuable knowledge, personalized solutions, and long-term support.

They help you stay efficient and ready for the future. If you want your factory or plant to run at its best, partnering with the right provider can make all the difference.